Flexible Electronics: Design and Application

Flexible electronics represent a significant evolution in the field of Computers & Electronics, moving beyond rigid circuit boards and static components to create devices that can bend, fold, and stretch without losing functionality. This innovative area of technology integrates pliable materials with electronic functionalities, paving the way for a new generation of adaptable and conformable devices. The core principle lies in fabricating electronic circuits and components on flexible substrates, which opens up vast possibilities for design and application across numerous industries.

Flexible electronics are transforming how we interact with technology, moving from traditional rigid circuit boards to adaptable, conformable systems. This shift allows for the creation of innovative devices that can bend, fold, or even stretch, maintaining their electronic capabilities. The integration of advanced materials and manufacturing processes is at the heart of this technological evolution, enabling unprecedented design freedom and functionality in a wide array of applications.

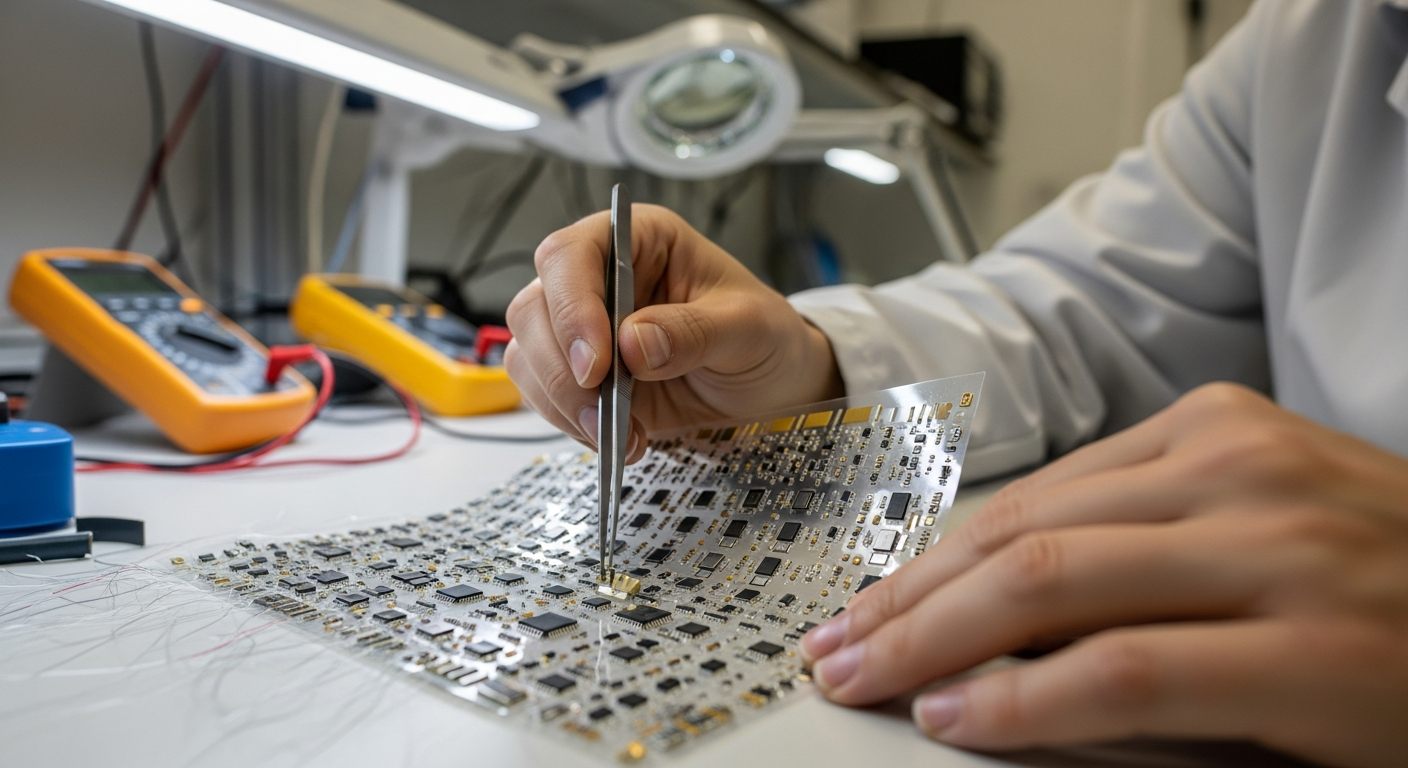

Foundations of Flexible Electronics: Materials and Components

The development of flexible electronics relies heavily on advancements in materials science and fabrication techniques. Unlike conventional rigid hardware, flexible circuits are often built on polymer substrates like polyimide or PEN, which offer durability and elasticity. Key components such as processors, semiconductors, and interconnects must be designed or adapted to withstand mechanical stress without compromising performance. Innovations in thin-film transistors and stretchable circuits are crucial for achieving robust and reliable flexible systems. These foundational elements dictate the overall performance and longevity of flexible electronic devices.

Advancements in Flexible Displays and Sensing Devices

One of the most visible applications of flexible electronics is in displays. Flexible displays, particularly those based on OLED technology, allow for screens that can be bent, rolled, or folded, leading to new form factors for smartphones, tablets, and televisions. Beyond visual interfaces, flexible electronics are revolutionizing sensing capabilities. Conformal sensors can be integrated directly onto skin or irregular surfaces to monitor vital signs, detect environmental changes, or provide haptic feedback. These devices offer enhanced user comfort and integration, pushing the boundaries of traditional electronic design.

Flexible Electronics in Wearables and Automation Systems

The inherent conformability of flexible electronics makes them ideal for wearables. Smart patches, e-textiles, and health monitoring gadgets can seamlessly integrate into clothing or adhere to the body, providing continuous data collection without discomfort. In robotics and automation, flexible electronics enable more dexterous and adaptable robots. Soft robots incorporating flexible sensors and actuators can navigate complex environments and interact safely with humans, opening doors for applications in manufacturing, healthcare, and exploration. This technology is driving the creation of more intelligent and responsive machines.

Future Trajectories: Innovation and Digital Integration

The future of flexible electronics is deeply intertwined with ongoing innovation in digital systems and advanced computing. Integrating flexible processors with artificial intelligence (AI) capabilities will lead to smarter, more intuitive devices. Advancements in flexible memory and storage solutions are critical for handling the increasing data generated by these next-generation electronics. Furthermore, the development of flexible networks will facilitate seamless communication between interconnected flexible gadgets and infrastructure, creating a truly ubiquitous computing environment. Researchers are also exploring self-healing flexible materials and energy harvesting solutions to further enhance the sustainability and autonomy of these electronic systems.

Economic Landscape of Flexible Electronics Development

The economic aspects of flexible electronics encompass significant investment in research and development, specialized manufacturing processes, and market penetration strategies. The cost drivers typically include the high price of advanced flexible substrates, the complexity of depositing and patterning electronic materials on non-traditional surfaces, and the need for precision manufacturing equipment. Prototyping costs can be substantial due to the iterative nature of design and material selection, while mass production requires scaling up these specialized processes, often leading to higher unit costs compared to rigid electronics. However, as the technology matures and economies of scale are achieved, these costs are expected to decrease, making flexible electronics more accessible for broader adoption.

| Category of Flexible Electronic Component | Example Provider Focus | Key Features | Cost Estimation (General Range/Factors) |

|---|---|---|---|

| Flexible Displays | LG Display, Samsung Display | Bendable, rollable, high resolution | High R&D, specialized manufacturing, material costs |

| Flexible Sensors | imec, MC10 | Conformal, biocompatible, real-time data | Custom design, integration complexity, material costs |

| Flexible Batteries | Jenax, Enfucell | Thin, conformable, safe, high energy density | Material innovation, safety testing, production scale |

| Flexible Printed Circuit Boards (FPCBs) | Fujikura, Sumitomo Electric | High density, robust, adaptable, compact | Design complexity, material type, production volume |

Prices, rates, or cost estimates mentioned in this article are based on the latest available information but may change over time. Independent research is advised before making financial decisions.

Flexible electronics represent a pivotal shift in the field of electronics, offering unparalleled adaptability and integration possibilities. From revolutionizing how we interact with displays and wearables to enhancing robotics and automation, this technology is set to redefine the landscape of digital devices. Continued innovation in materials, manufacturing, and AI integration will be key to unlocking the full potential of these adaptable systems and driving their widespread adoption across various sectors globally.